Outotec Turula

Światowy lider w dziedzinie technologii przetwarzania minerałów

Dzięki oprogramowaniu WeldEye do zarządzania spawaniem osiąga nowe poziomy technologiczne.

Czytnik Smart Reader skanuje specyfikację procedury spawania.

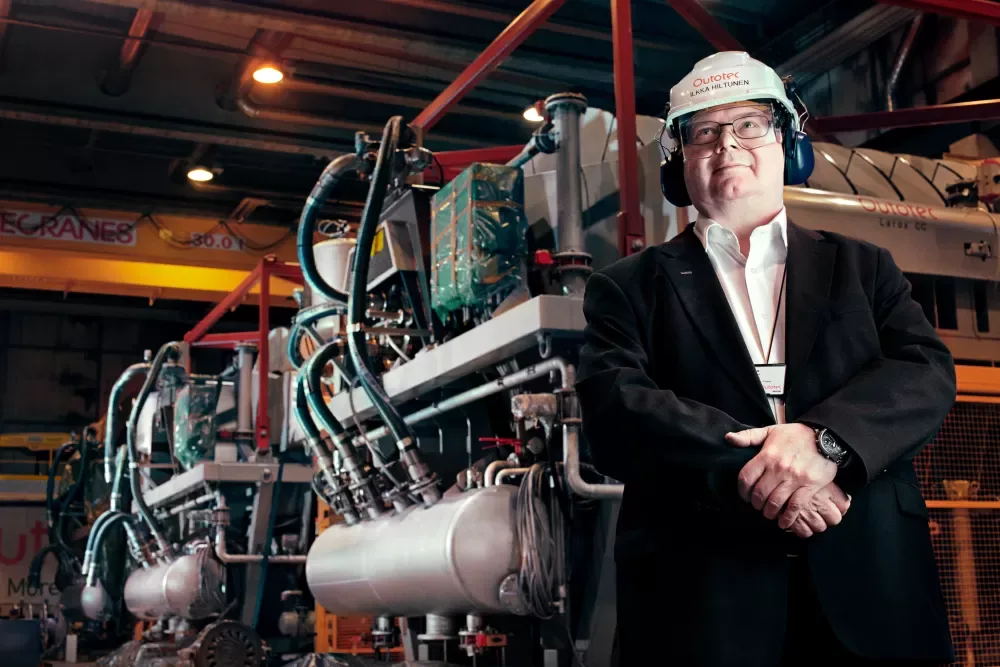

Starszy doradca Ilkka Hiltunen z trzema solidnymi filtrami dyskowymi, które mają zostać wysłane do Brazylii.

Kari Koistinen, Ilkka Hiltunen i Rauno Kakkola z Outotec Turula.

Prace w toku w warsztacie Outotec Turula.

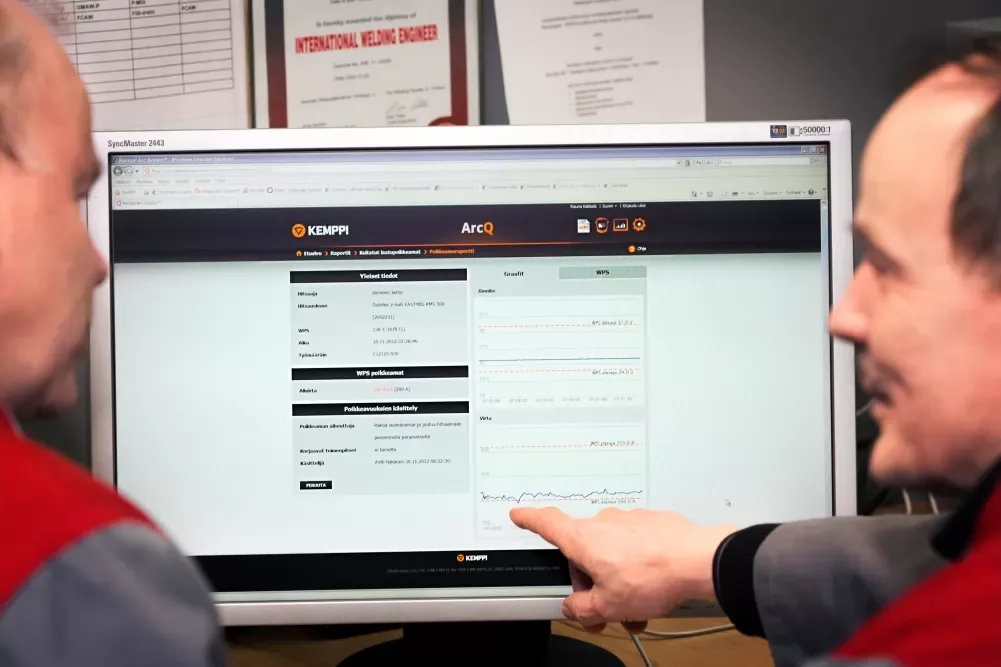

Oprogramowanie do zarządzania spawaniem w produkcji spawalniczej Outotec Turula.

Rauno Kakkola i Kari Koistinen analizują raport o odchyleniach w interfejsie użytkownika oprogramowania.

Kemppi SuperSnake przy pracy.

Przejrzyj naszą ofertę

Rodzina produktów

WeldEye to uniwersalne rozwiązanie do zarządzania pracami spawalniczymi podczas produkcji elementów metalowych.