Outotec Turula

Global leder innenfor anrikningsteknologi

WeldEye-programvare for sveisestyring tar foretaket til nye høyder

Smart Reader skanner en sveiseprosedyrespesifikasjon.

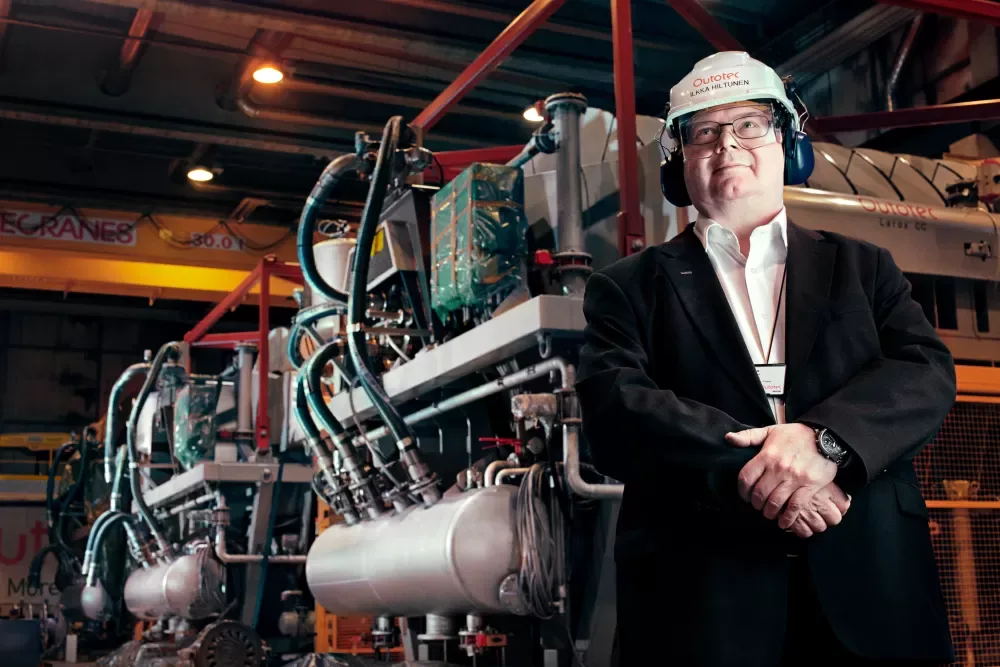

Seniorrådgiver Ilkka Hiltunen med tre robuste skivefiltre som skal sendes til Brasil.

Kari Koistinen, Ilkka Hiltunen og Rauno Kakkola fra Outotec Turula.

Pågående arbeid på Outotecs verksted i Turula.

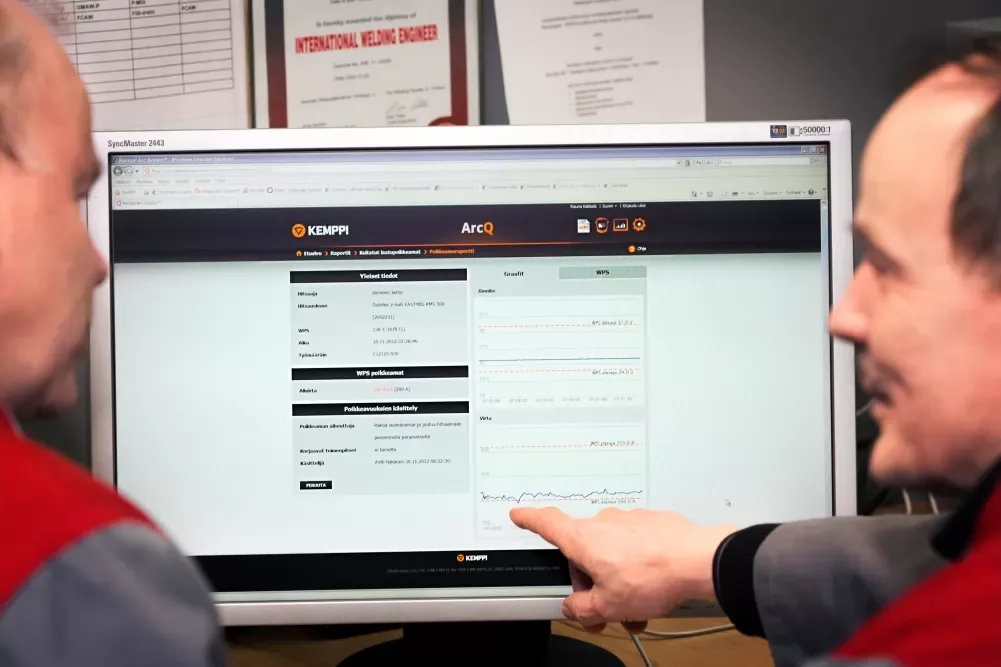

Programvareløsningen for sveisestyring er i bruk i Outotec Turulas sveiseproduksjon.

Rauno Kakkola og Kari Koistinen analyserer en avviksrapport om programvarens brukergrensesnitt.

Kemppi SuperSnake i arbeid.

Featured Solutions

Produktfamilie

WeldEye è una soluzione universale per gestire la produzione di saldatura.